|

Our Solutions Working PlatformsAt Geoworks, we specialise in providing cutting-edge geosynthetic solutions designed to meet the rigorous demands of modern civil engineering and construction projects. Our expertise in geosynthetics positions us as a leader in crafting safe, durable, and efficient working platforms, essential for the operation of specialist and heavy machinery.

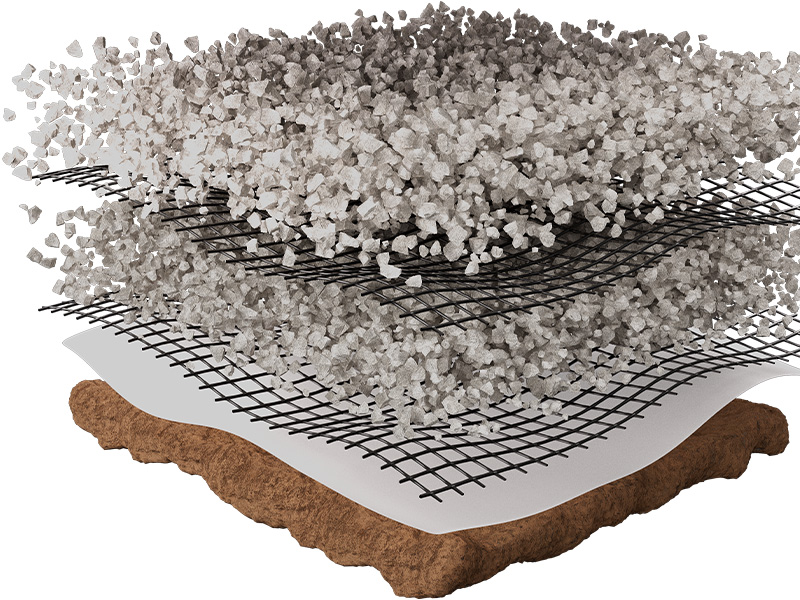

The Need for Safe Working PlatformsThe foundation of any successful construction or engineering project lies in the safety and stability of its working platforms. These platforms must be capable of supporting heavy machinery, such as cranes, excavators, and dump trucks, ensuring operational efficiency and worker safety. The challenges of diverse ground conditions and the need for sustainability demand innovative solutions. Geosynthetics from Geoworks offer an optimal foundation for creating robust working platforms. Our products are engineered to distribute loads evenly, improve ground stability, and enhance site safety, making them ideal for supporting heavy and specialist machinery. Key Benefits:Load Distribution: Our geosynthetics effectively spread the load over a wider area, reducing ground pressure and preventing subsidence, even in soft soil conditions. Ground Stabilisation: By reinforcing the ground, our solutions ensure a firm foundation for working platforms, enhancing the safety and efficiency of machinery operation. Durability: Designed to withstand harsh environmental conditions and heavy loads, our geosynthetics extend the lifespan of working platforms. Sustainability: Our environmentally friendly solutions contribute to sustainable construction practices by minimising the need for natural resources and reducing carbon footprint.

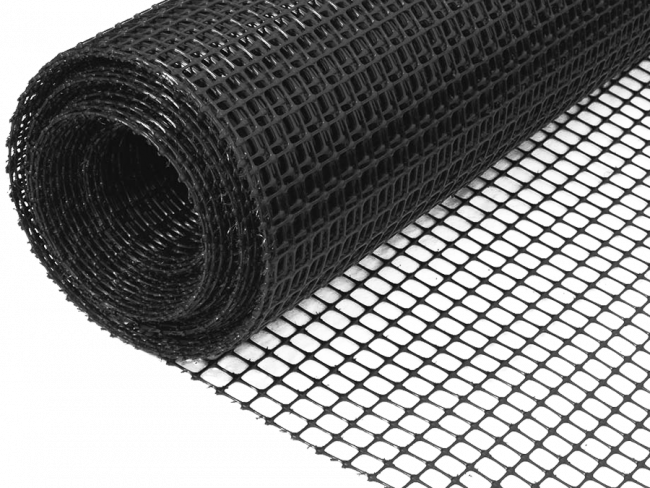

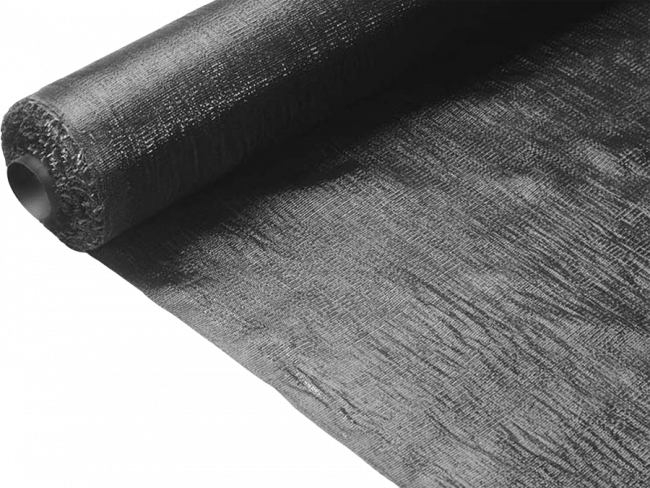

Working platform solutionsOur experience and leadership have allowed us to develop a range of unique and innovative products, from geotextiles to geogrids, that give specifiers, contractors, and asset owners significant benefits.

Working platforms in numbersOur geosynthetic solutions have been used on thousands of projects to provide significant cost savings as well as promote sustainability and reduce emissions.

Proven solutionsGeogrids for Piling PlatformsGeogrids are an under-utilised solution, which can reduce the thickness of a working platform, typically by 50%, resulting in substantially reduced construction cost and time. Along with significant cost reductions, geogrids improve site health and safety, accelerate construction timescales and reduce the project’s overall environmental impact. This is because when granular particles are compacted over these grids, they partially penetrate and project through the apertures to create a stiff and positive interlock. The load dispersal effect from the interlocking mechanism increases shearing resistance within the aggregates, improving compaction and allowing the granular thickness to be decreased – ultimately reducing construction time and cost. Ready to get involved Supporting tender bidsWe’re an advocate of early engagement because if a Geoworks engineering manager is engaged at the tender stage, the impact on the savings to reduce time and money can also assist contractors in winning tenders. Another benefit of early engagement is that geogrids can be manufactured to the exact width that the contractor needs, suiting the site-specific requirements and creating an even more cost-effective grid. Simply removing a longitudinal overlap in the geogrid layout can save a further 10 per cent in product costs alone. Small changes but big savings are available. However, all isn’t lost if engagement comes afterwards as savings can still be introduced.

More solutions

Roads and Temporary Roads Solutions for roads and temporary roads which solve common everyday failures and annoyances of specifiers and installers alike.

Compounds and Haul Roads Use geosynthetics to substantially reduce construction cost and time while accelerating timescales.

Erosion control Reinforce your existing structures instead of creating concrete solutions.

Sustainable Urban Drainage systems These systems aim to mimic natural water processes, helping to reduce flooding, improve water quality, and enhance overall urban environmental sustainability.

Horse manege Solutions for horse manege and gallop areas using a combination of granular materials, silica sands and our woven and non woven geosynthetics.

Tree root protection Avoid a concrete jungle by including flexible rooting volume and growing trees in your urban developments.

Contact usWhether you are looking for live project support or are in the initial stages of specification, we are always on hand and happy to help. Alternatively call us on 01543 440 480. |