|

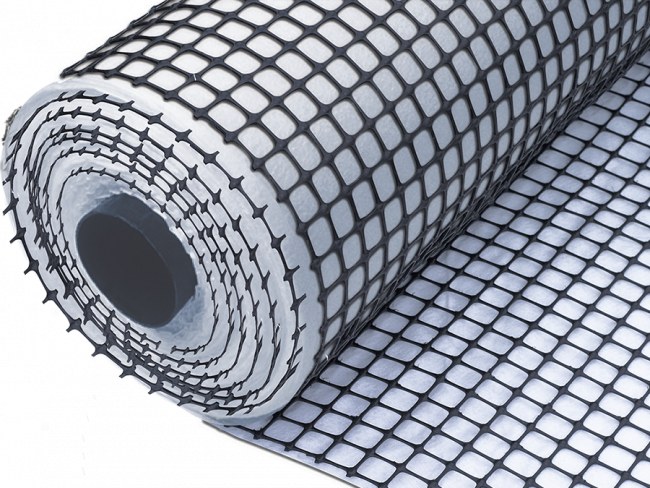

Our products are now on SpecifiedBy Find us on SpecifiedBy GeocompositesGeocomposites consist of one or more geosynthetics, specifically a geogrid, geotextile or geomembrane with another material. They enable installations to be quicker, easier and less labour-intensive by providing a combination of two geosynthetic products into one, removing processes from an installation.

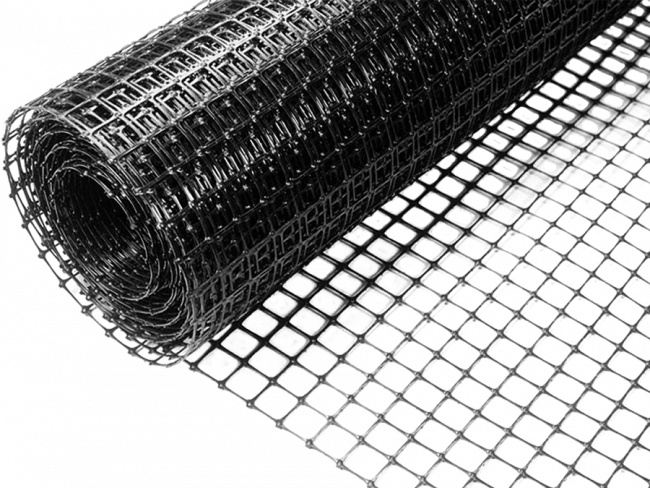

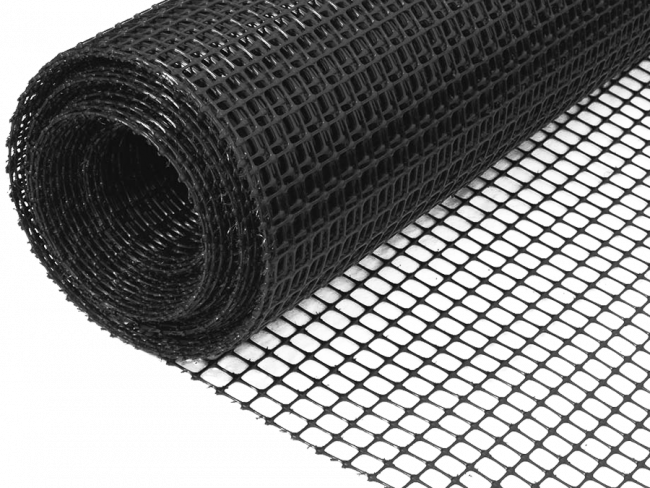

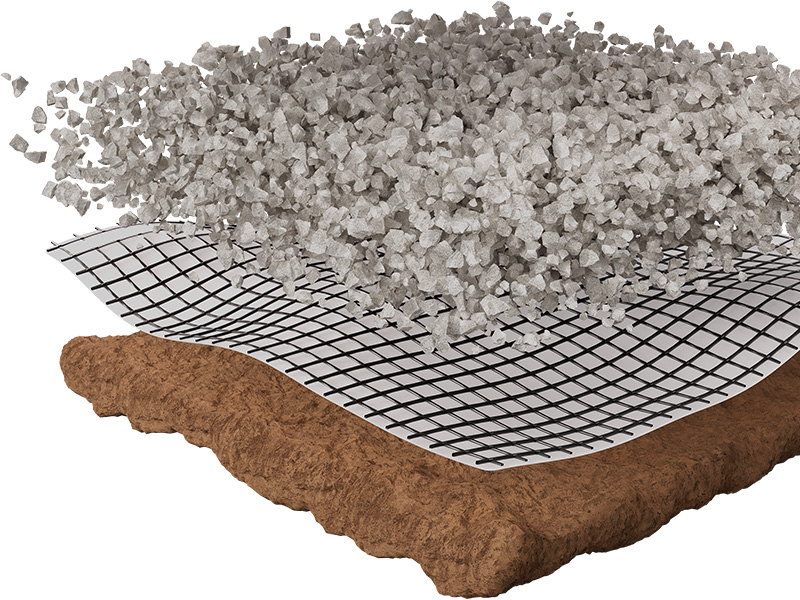

Geogrids and geotextiles are often used together to provide reinforcement, separation, and filtration properties. This can be on projects such as haul roads, permanent roads, working platforms and compounds where there is low formation CBR. Geogrids are installed due to their exceptional load-bearing capacity and reinforcement capabilities. These materials enhance the overall strength and stability of the road surface, ensuring it can withstand the heavy loads and constant traffic associated with haulage operations. Nonwoven geotextiles delivers excellent durability and drainage function in addition to its very high water flow capability, making them ideal in filtration and drainage applications, with long term separation. Our geocomposites combine both products into one thermally bonded solution, providing significant time, labour and cost savings by removing the need for two separate solutions. Thanks to its multi-purpose function, you can save time when acquiring materials, and achieve an overall quicker installation.

Find out how much money and carbon you can saveWhen constructing a temporary road you can save money and decrease your carbon footprint. By using a Geoworks biaxial geogrid you could dramatically reduce the amount of aggregate required on your project. Our easy-to-use calculator can give you an estimation of cost and carbon savings.

Network Rail approval for TerraGrid ProTerraGrid Pro 3030L is approved by Network Rail with Certificate of Full Acceptance number PA05/05826.

To achieve this TerraGrid Pro underwent a vigorous auditing process, including having to provide justification for the product by demonstrating its monetary, safety and performance benefits to Network Rail. TerraGrid Pro 3030L polypropylene biaxial geogrid features a large aperture, suited to reinforcing the railway ballast layer. This reduces ballast settlement and extends the time between subsequent maintenance work following ballast renewal. The reinforcing element is a Specific Condition of Network Rail acceptance, which requires CE Marking in accordance with BS EN 13250 for reinforcement materials used in contact with ballast. The high tensile strength design of TerraGrid Pro is widely recognised as an effective method of stabilising ballast or soil through reinforcement. The high-strength polymer grid interlocks with the ballast or stone, confining the material to improve load dispersal and limit lateral movement under load. Geogrid ranges

|