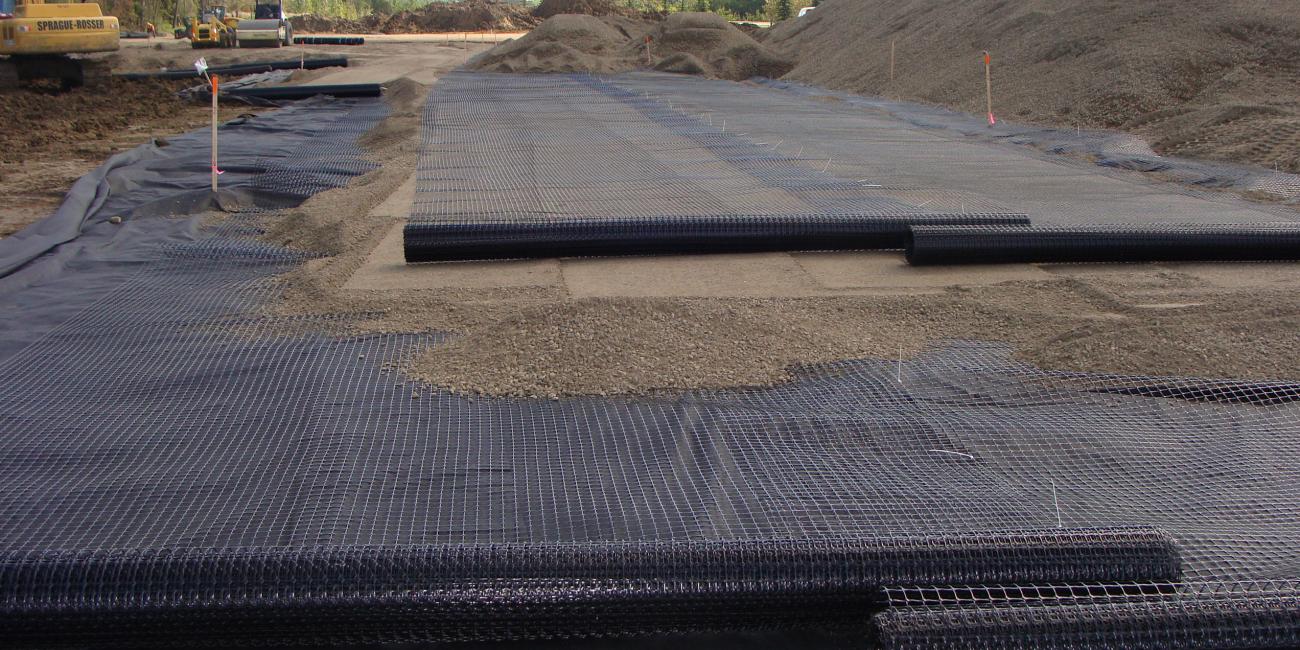

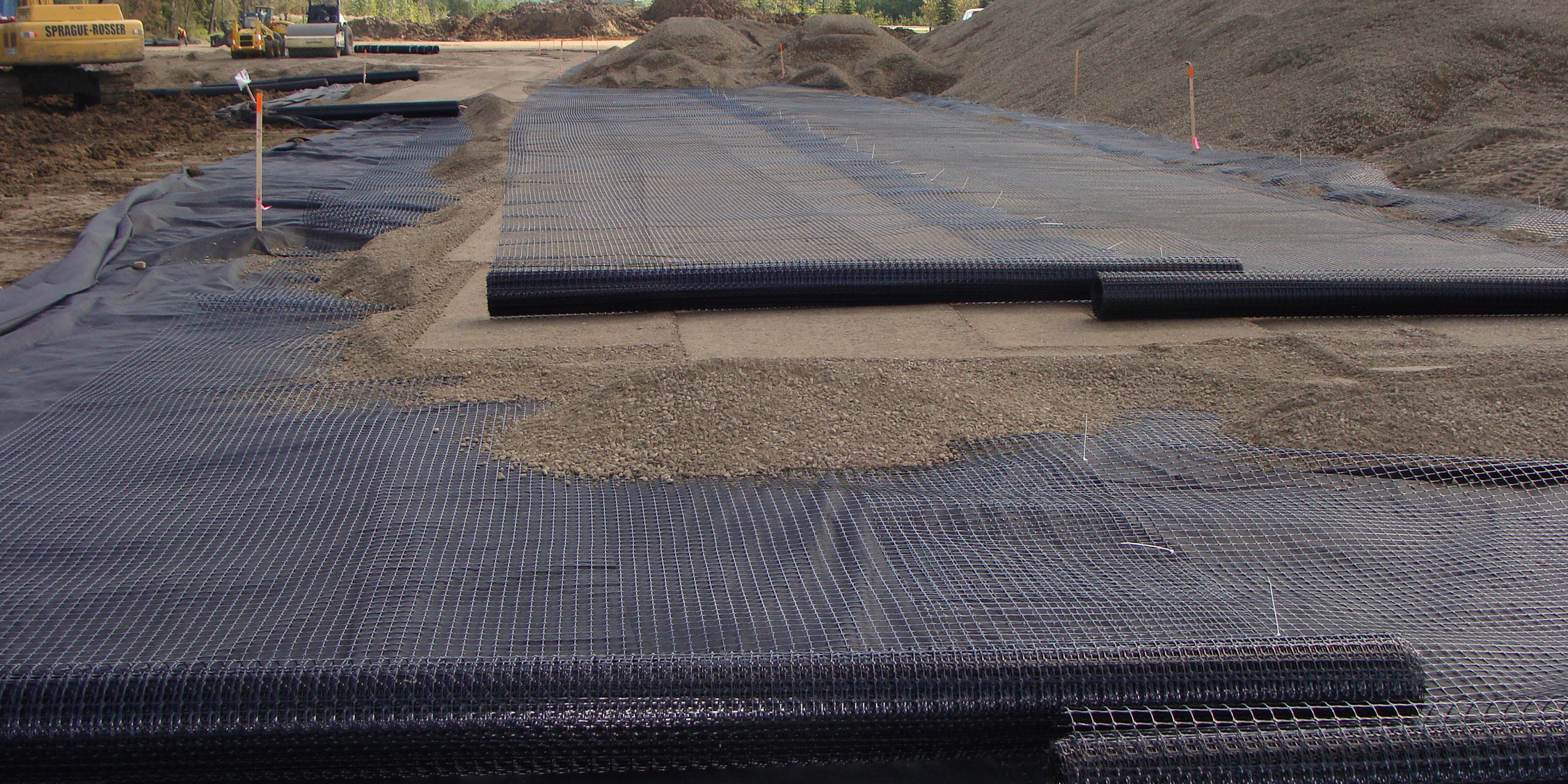

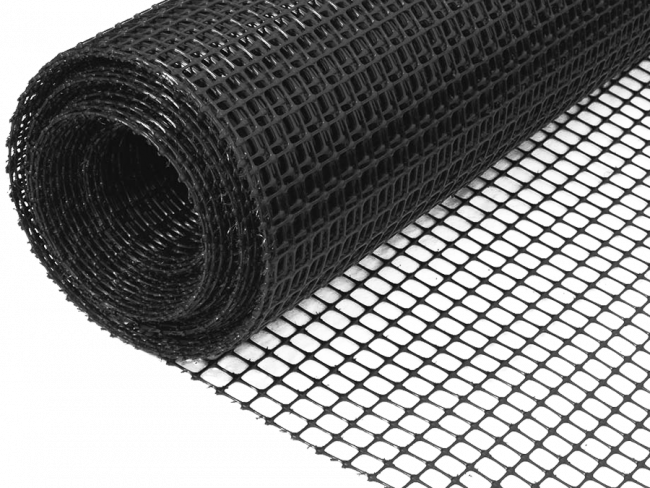

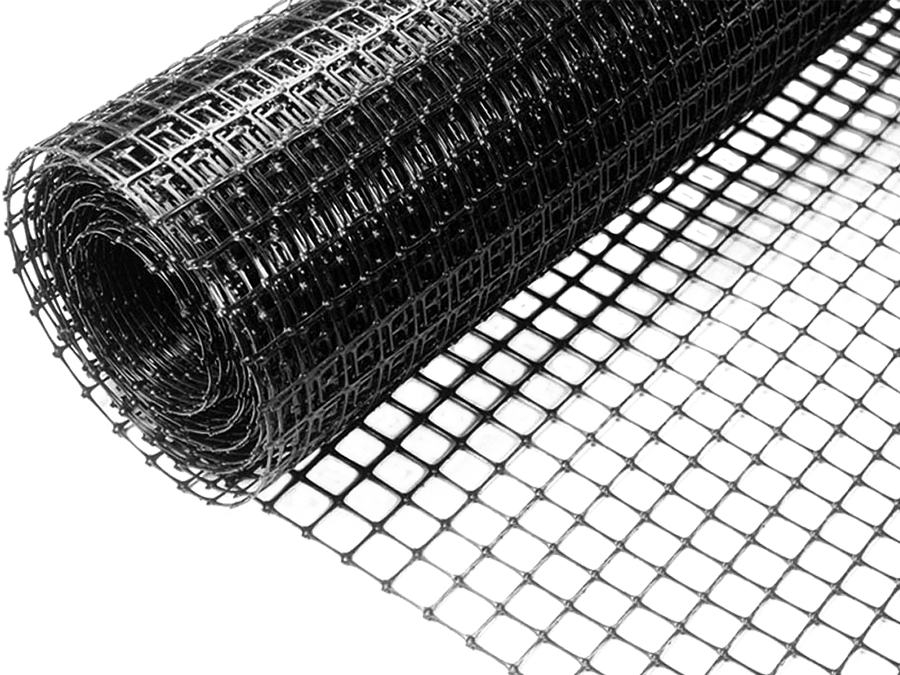

Applications and benefitsTerraGrid Core allows granular particles to be compacted over them, partially penetrating and projecting through the apertures. This creates a strong and positive interlock; the interlocking mechanism increases shearing resistance within the soil, improving compaction and allowing the sub-base thickness to be decreased while dispersing loads. TerraGrid Core comes as standard in 4m roll widths. For haul road applications, this can often completely eliminate the need for overlaps across the width of the road, significantly reducing wastage. With TerraGrid Core, you can reduce construction time, costs and even CO2e. Benefits of TerraGrid Core

Products

Achieve significant savingsReduce your projects carbon emissionsOur geogrids can play a significant role in reducing carbon emissions across a project. There's numerous ways this is achieved, including:

Continuing Professional DevelopmentGround engineering solutionsThis CPD will help you to understand the background of our range of products on offer, where they’re used, what makes them different, and what to look out for when specifying.

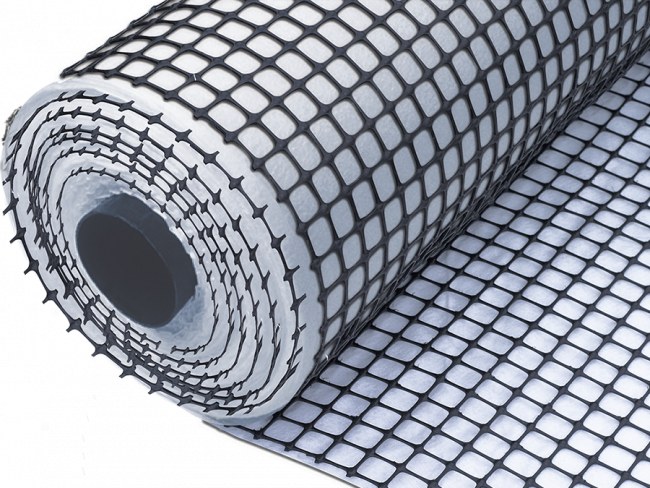

Combined geogrid and geotextileHave you considered TerraGrid Core Composite?Achieve time savings when acquiring materials and overall quicker installations, thanks to TerraGrid Core Composite, an all-in-one solution that performs as both a biaxial geogrid and a geotextile. TerraGrid Core Composite consists of nonwoven geotextile thermally bonded to our popular SX range of geogrid. It provides the functions of reinforcement, separation and filtration into one single product, rather than having to use two separate solutions, which offers significant savings.

Contact usWhether you are looking for live project support or are in the initial stages of specification, we are always on hand and happy to help. Alternatively call us on 01543 440 480. See what you can achieve with our geogrids

Erosion control Reinforce your existing structures instead of creating concrete solutions.

Working Platforms Create and maintain a safe environment with our piling platform solutions.

Compounds and Haul Roads Use geosynthetics to substantially reduce construction cost and time while accelerating timescales. Similar ranges

| ||||||||||||||||